The Bristol Company

Excerpt from Naugatuck Daily News – Saturday, August 31, 1946

World War II - History Edition

Bristol Company Contributed Mechanisms For Atomic Bomb Development Project

Sonar Gear For Underwater Detection Of Submarines Also A Product

The Bristol Company, which manufactures automatic control and recording instruments and rocket servos, was in peacetime an important source of war equipment. When these articles became necessities for war equipment, the concern turned out innumerable types of equipment used in the armed services.

It was in war production that it was realized when the revelations came out following the first Atom Bomb explosion that the plant had been contributing to the Atomic bomb project.

In the past, use was made of the detection of submarines, with work on "confidential" instruments which developed the Bristol Company participation.

The plant had made instruments for detection of submarines used by the Army and Navy, in addition to the more “confidential” line of products for use in war strategics, fire detection, and diesel engine performance. The company also built torpedo exploder mechanisms for the Navy as a subcontractor on these devices furnished to other manufacturers.

On July 29, 1945, Bristol employees were awarded the Army-Navy “E” for outstanding war performance meeting Army and Navy production requirements. In a statement, Under-Secretary of War, Robert P. Patterson, made the award – “You men are making an outstanding contribution to victory. You have every reason to be proud of the record you are making. Your accomplishment stands as an example to all Americans.”

Four stars were later added to the flag in recognition of additional war production achievement.

It was recognized that the role of employees in the war effort was well illustrated by the extent of participation in war bond purchases. During October, 1942 an overall bond allotment of 24 percent of the total payroll was reached. The Treasury Department presented the “T” flag for employees the following summer.

In October, 1943, the percentage increased to 39 percent in bond investment. At the time the “E” was awarded, Bristol employees were at a 43 percent level of investment and climbing steadily. For their work and support in the war effort, the drive showed the verified results of Bristol workers’ participation.

Employees in Victory activities also contributed in Red Cross and War Fund drives, including the Community War Fund Institute, plus in 1944 and 1945.

Excerpt from Naugatuck Daily News – Monday, September 15, 1947

Industrial Exhibit Supplement

Bristol Co.’s Magic Aid To Nation In War, Peace

FORWARD - The Bristol Company is a manufacturer of many types of automatic control and recording instruments, and also a line of mill supply products including belt lacing, and socket set and cap screws. There is scarcely a product used in everyday life — food, clothing, paper, automobiles, gasoline, rubber goods, cosmetics, and even safety for aircraft — that is not tied, in some fashion, to the instruments of the type manufactured by The Bristol Company.

In the year 1889, when America stood on the threshold of a great industrial era, The Bristol Company was founded by Professor William H. Bristol and his brother Franklin. Professor Bristol was born in Waterbury in 1859, the son of long New England ancestry, and indeed gifted with an inquiring mind, industrious application, and broad vision.

He graduated from the public schools of Naugatuck and the Stevens Institute of Technology at Hoboken, New Jersey, with the degree of Mechanical Engineering. Later he became instructor and afterwards Professor of Mathematics at his alma mater.

It was while pursuing his educational studies that he worked on a design of an effective means of joining leather belting. He succeeded in inventing a simple, steel fastener for that purpose that was soon to have wide application. The Bristol Company was organized to manufacture, and develop and promote the sale of this lacing.

At first, manufacturing operations were undertaken in Franklin B. Bristol’s barn, located in Naugatuck, using one operator and a limited amount of machinery. But soon, because of the great demand for the product, larger quarters and more operators and machinery were needed. In 1892, manufacturing operations were removed to Platts Mills in South Waterbury on the west bank of the Naugatuck River. Here, railroad facilities were available and ample land for expansion.

Experimental Work

Also, during this time, experimental work was started on various forms of modified Bourdon tubes in an effort to perfect a compound instrument that would serve as a gauge. Soon a satisfactory combination of this type was being manufactured and sold in large quantities. A practical outgrowth was the recording pressure gauge which became the foundation for the recording element of flat, metal-tube bourdon tubes. This was followed by the building of indicators for oil, coal, copper tubing, which, in turn, led to the building of recording instruments for temperature, pressure, voltage, watt-hours, amperes, and gas. These instruments, developed for measuring and continuously recording all three of these variables, were then manufactured together as the “temperature and pressure recorders,” were exhibited at the World’s Fair in Chicago in 1893. Awards of merit and honorable mention were granted at this Fair, and also at the Paris Exposition in 1900, as well as at the Pan-Pacific Exposition in 1915.

In 1906, the William H. Bristol Electric Pyrometer Company was organized by Professor Bristol for the manufacture of a line of instruments involving the use of resisters in the indicating and recording forms. Instruments of this type were built for every commercial use, using a base metal or rare metals, including of platinum, iridium, and rhodium. A complete line of indicating and recording instruments followed, for industrial requirements. However, in 1915, this company (The Bristol Company) merged with The Bristol Company and the manufacture of the Electric Pyrometers was included in the plant facilities at Waterbury.

Steady Growth

During the past several decades, the growth of The Bristol Company has not only been due to development of its ability to develop and design instruments for both laboratory and shop use, but also to anticipate the desire for these special instruments, so that the facilities were made ready and available when needed.

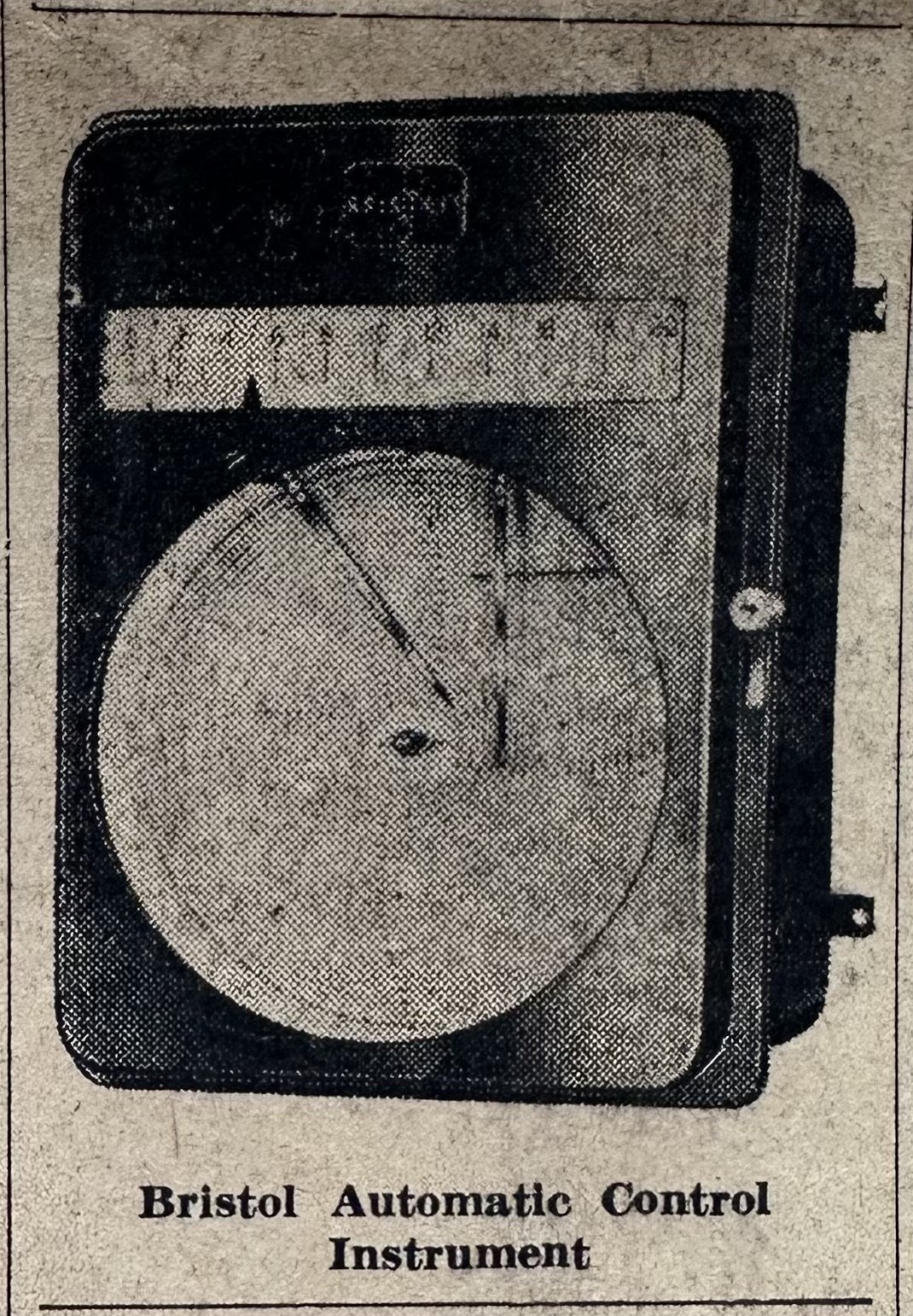

Among the many types of devices manufactured by The Bristol Company are electrical and pneumatic instruments for recording and automatically controlling temperature, pressure, vacuum, draft, absolute pressure, flow of fluids in pipes, liquid and water level, pH value, humidity, mechanical operation and motion; recorders for speed of travel and rotation, voltage and current; telemetering instruments; controllers of time and sequence; photo-electric and electrical pyrometer recorders; special meters and combustion and atmospheric-operated and actuated valves.

Great Boon

The emergence of the Coordinated Process Control System, originally conceived by The Bristol Company, has proved to be a great boon in modern manufacturing. Practically no material or product used in war’s warfare or in peacetime development escapes the automatic check of automatic control instruments. Such applications are found in steel mills, paper mills, chemical plants, textile mills, oil and gas refining, electric power production and distribution, water and sewage disposal, rubber manufacturing, food processing, aircraft and shipbuilding industries, and a wide range of other fields. These instruments improve quality, speed, flow, uniformity, and cost-efficiency.

In 1913, The Bristol Company became actively engaged in socket cap screw manufacturing. The H. T. Cushman Company (not visible — possibly “(using for driving)” or similar) — manufactured socket head cap screws, located in Waterbury, acquired that business in 1917, and cap screws were then marketed under the trade name of “Bristol.”

“Bristol” screws and socket heads improved through the years by the use of newer grades of steel and alloys, and better heat treating equipment and methods as they were developed. In 1940, a complete line of hex socket set and cap screws were added. Today, The Bristol Company Mill Supply Products include the following:

Steel Belt Lacing, Pipe Plugs, Set Screws and Wrenches, Cap Screws and Wrenches.

During World War I, manufacturing facilities were engaged in the making of air speed indicators, venturi and orifice tubes, recording thermometers for airplanes, ballast gauges for dirigibles, hydroport leak detectors, and gasoline level indicators; in addition to supplying the industrial concerns of the United States with the regular line of automatic recording and controlling instruments.

Howard H. Bristol

In 1920, because of a desire to devote more time to experimentation and the designing of new products, Professor Bristol placed the active management of The Bristol Company with his nephew, Howard H. Bristol.

Howard H. Bristol received his engineering degree from Stevens Institute in 1910, and shortly after became employed with The Bristol Company. He organized a large engineering department in 1912, and became chief engineer. He continued in that capacity until his appointment as Vice-President and General Manager in 1920.

Professor William H. Bristol died in 1930. His loss was felt very keenly, not only by The Bristol Company, but by the entire instrument industry.

Howard H. Bristol was then elected President of the company. He continues to the present time in that position with the present officers of the company as: Frank B. Adams, Chairman of Board; William H. Feath, Vice-President and Treasurer; Carlton J. Hine, Vice-President and Advisory Engineer; Lawrence A. Wiegand, Secretary and Assistant Treasurer.

After Pearl Harbor, The Bristol Company manufacturing facilities were greatly expanded to take care of the enormous demands for its regular line of products and to handle special control devices for the U.S. Army and Navy, including aircraft instruments and diesel engine pyrometers. In particular, torpedo exploder mechanisms were built for the Navy. In addition, numerous confidential projects were undertaken, developed, and manufactured for the armed forces, such as sonar gear for the underwater detection of submarines. Bristol also contributed, in an extremely important way, to the atomic bomb projects.

During World War II, The Bristol Company furnished the instrumentation required for manufacturing such essential materials and equipment as: T.N.T., Smokeless Powder, Synthetic Rubber, Aviation Gasoline, R.D.T., Penicillin, D.D.T., Tanks, Airplanes, special chemicals, and in the production of aluminum, magnesium and steel.

Bristol facilities for manufacturing socket screws were also greatly expanded to meet the demand for their use in field telephone sets, electronic detectors, aircraft radio equipment, bomber communication systems, walkie-talkies, test sets, airplane instrument panels, and aerial cameras.

Loyal Employees

When the history of successful institutions is reviewed, it is found that they are built around a nucleus of loyal and industrious men and women. In June 1944, The Bristol Company Quarter-Century Club was formed for the express purpose of both recognizing and honoring those persons who had faithfully and industriously performed their tasks for periods of 25 years or more. In the year 1919, in which the youngest of Quarter-Century Club members in years of service started, there were 600 employees on The Bristol Company payroll. Nearly 17 per cent of that number, 100 persons, were represented at the first Quarter-Century Club banquet. Each member was presented with a gold service pin and twenty-five dollars in silver. The Bristol Company Quarter-Century Club is convened every June for further honoring its members by the company and also for welcoming new members into the organization.

Nation-Wide Organization

A nation-wide organization for the sale and service of Bristol Products has been steadily built up over the years. There are branch factories in Akron, Chicago, San Francisco and Havana, Cuba. In addition, branch offices are located at Boston, New York, Philadelphia, Pittsburgh, Cleveland, Akron, Birmingham, Detroit, Chicago, St. Louis, Houston, Salt Lake City, Denver, Seattle, Los Angeles, and San Francisco; and many representatives, to assist in solving industrial instrumentation problems, are found in the larger cities of America.

In 1932, an English affiliate, Bristol’s Instrument Company, Ltd., was established in London, England, and two years later The Bristol Company of Canada, Ltd., was established at Toronto, Ontario, to serve more efficiently the English and Canadian markets for Bristol products. Qualified agents and distributors of Bristol manufactures may be found in all the principal countries of the world.

Naugatuck Daily News – Monday, September 15, 1947

Naugatuck Daily News – Monday, September 15, 1947

Naugatuck Daily News – Monday, September 15, 1947