Peter Paul

Peter Paul, Inc.

Quality Candy since 1919

By Sandy Clark

There are slight connections between the candy company Peter Paul Inc., the Rubber Company, and the Naugatuck Chemical Company.

The Peter Paul candy company is named after Peter Paul Halijian, an Armenian immigrant who came to America in 1870.

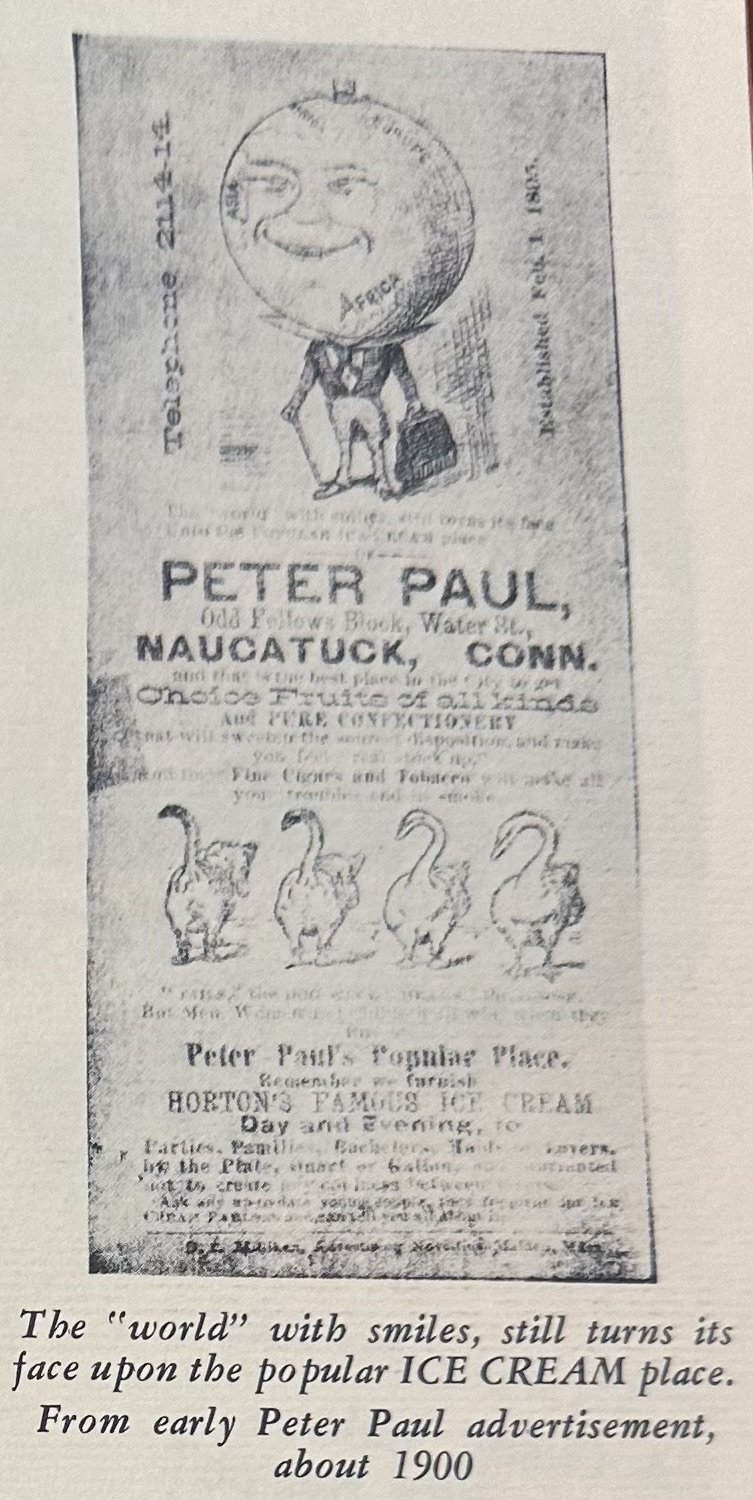

Peter Paul found work in the Rubber Company in Naugatuck and was paid on a piecework basis. He often reached his quota by early afternoon, leaving him free to pursue activities in shops in Naugatuck and in Torrington, where he sold ice cream and candy. He also operated a fruit and ice candy stand with two brothers. An 1899 advertisement read:

“Good candies and low prices. Fruits and nuts of all kinds. Peter Paul!”

Often he sold his fresh homemade candy from a basket to commuters in the railroad station.

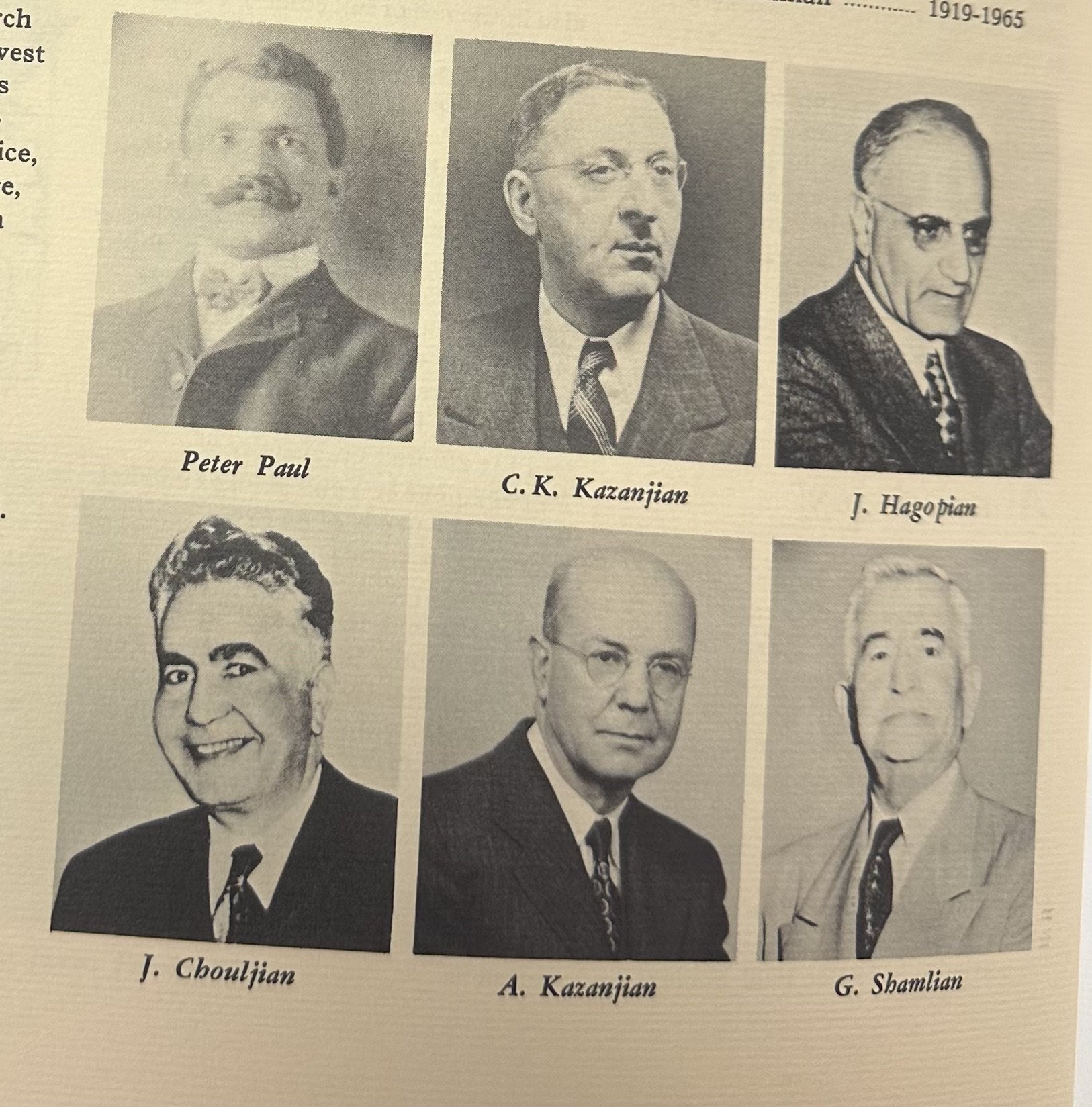

By 1919, Mr. Halijian’s recipes and ideas had grown so popular that he and a few friends decided to start a candy business. The other five founders, also Armenian immigrants, included Cal Kazanjian (Peter Paul’s brother-in-law), and George Shamlian, who before World War I was a chemist for the Naugatuck Chemical Company. He became an officer, director, and president of the company.

Artin Kazanjian (Cal’s cousin) provided the muscle needed to stir the huge steaming kettles required for candy making, but his specialty was product research.

Another founder, Jacob Choulian, was an army chef during the First World War and a cook in Duffy’s Restaurant. He joined Peter Paul as a kitchen employee and worked his way up the ranks to production chief and director by 1917.

Jacob Hagopian, a former cook for the Waterbury railroad station and Jake Choulian’s cousin, married one of Cal’s sisters and joined the founders in organizing the new company in New Haven. His expertise was traffic, shipping and finance.

The company originated on Webster Street in New Haven in a 50-foot by 60-foot loft. Candy was made by night because there was no refrigeration. The owners were anxious to sell the candies the next day while it was still fresh. The founders’ philosophy was to give customers a fresh product and receive a fair return for their money.

The first candy included nuts, fruit, coconut and chocolate and was called KONABAR. Once the company was established, Peter Paul hired Harry Tatigian, a candy maker from Bridgeport. In 1926, he and George Shamlian developed the present formula for MOUNDS.

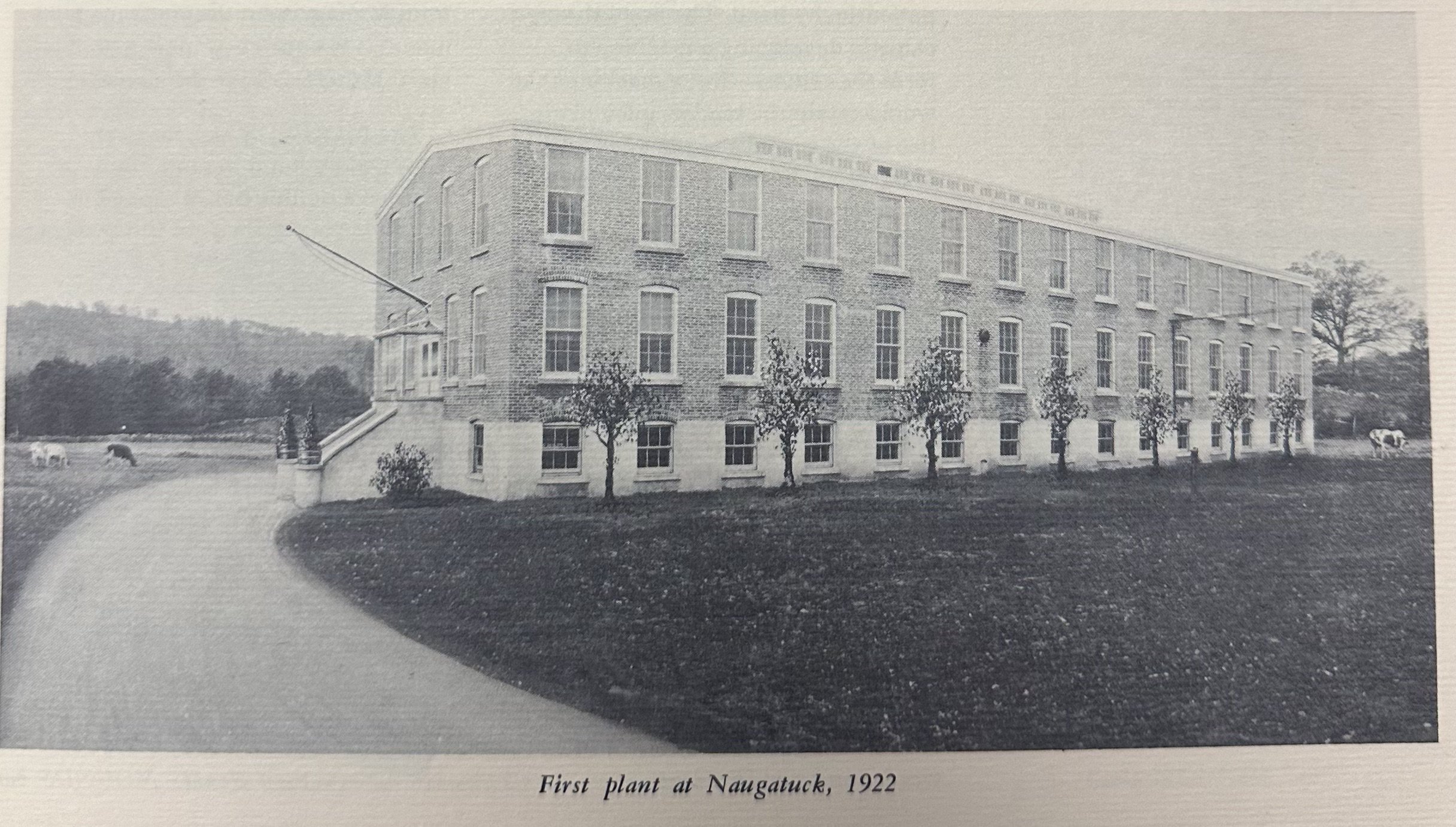

Because MOUNDS was a big success and demand for it grew rapidly, the candy makers needed new quarters. Friends and business men in Naugatuck helped the company relocate to Naugatuck in 1922.

Peter Paul Halijian died in 1927, and Cal Kazanjian became president. He had been secretary and treasurer. Like the original founders, he was often engaged in all aspects of the industry.

In 1929, the company made its first acquisition, the candy business of J. N. Collins Co. by which it became producers of WALNUTTOS, HONEY SCOTCH, and BUTTER SCOTCH CARAMELS & CHOCETTES. These lines helped build sales and later proved to be valuable assets.

As the sale of MOUNDS continued to grow, the management realized the need for faster production. Molding the coconut centers and dipping them in chocolate was slow and tedious. After years of experimentation, a machine was developed to produce more candy and still retain Peter Paul quality.

About the same time, suppliers to the company developed chocolate coating machines and crude refrigerated conveyors which permitted the first “line” of candy production to be assembled. The company adjusted a bar soap wrapping machine to accommodate the shape and size of MOUNDS. By 1932, the line was automated.

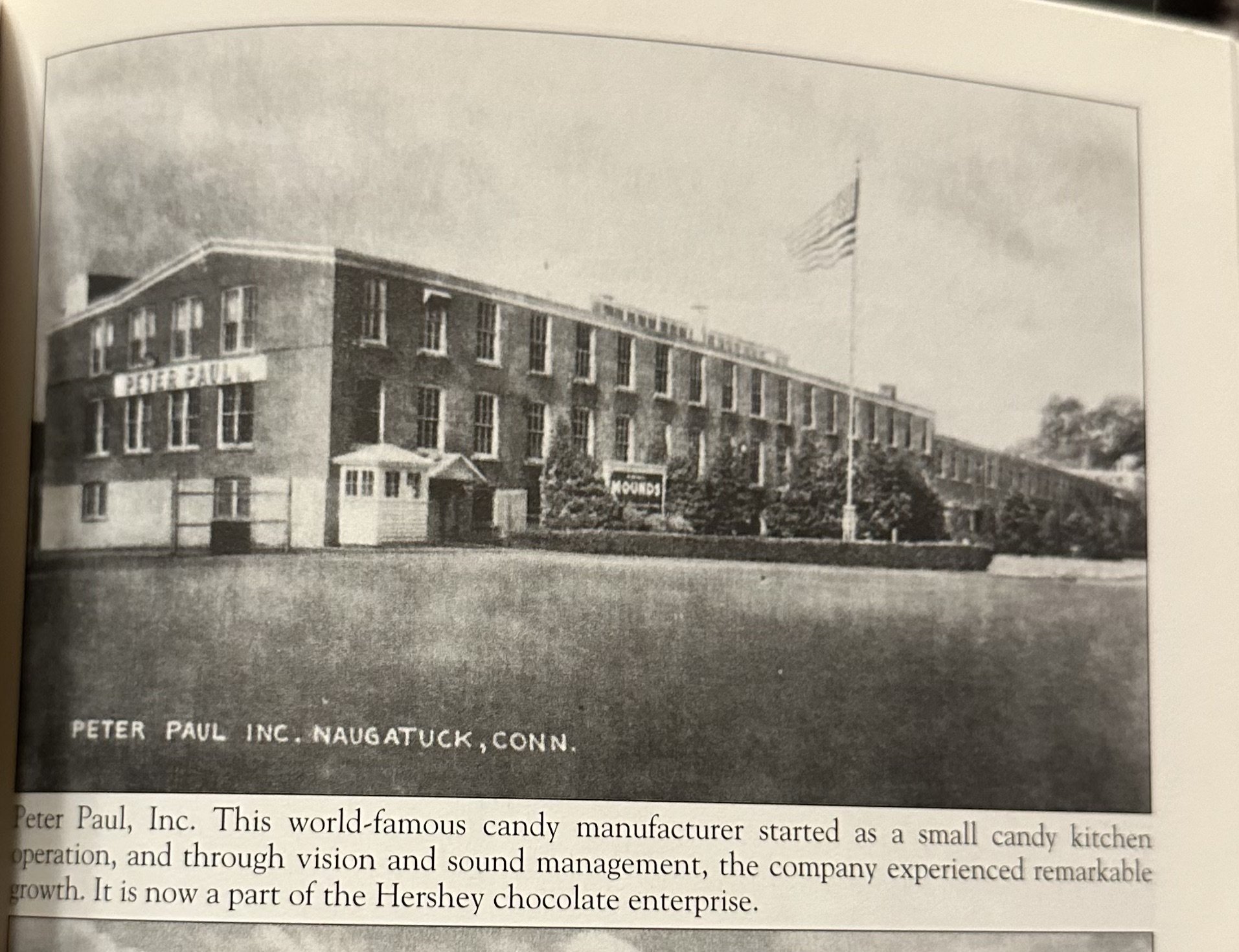

The Peter Paul, Inc. building was constructed in 1922 on New Haven Road.

Source

Naugatuck Historical Society Newsletter

Volume 12, Issue 3

May - June 2007

Peter Paul, Inc., Part II

The effect of the Great Depression and World War II on the company.

By Sandy Clark

The Great Depression made a large drop in Company profits, and cutting quality was very tempting; but Peter Paul made a bold decision to double the size of MOUNDS for the same five-cent price. There was an immediate large increase in sales.

Soon Peter Paul MOUNDS found their way across the country. They were advertised on national radio with the slogan “What a bar for 5 cents.” In 1934, a milk chocolate version of MOUNDS was introduced and called DREAMS. A $60,000 addition was built on the existing plant to meet the demands of candy lovers who adored coconut. In keeping with the philosophy of providing the freshest possible product, the company also doubled the speed with which it sent it from the rule. In 1939, Peter Paul opened a plant in Los Angeles, California; in 1948, a plant opened in Dallas, Texas; in 1958, another opened in Frankfort, Indiana.

In the late 1930’s Peter Paul found itself in the gum business. The result of another acquisition, it made a small pack of gum called “Ten Crown Activated Charcoal Gum.”

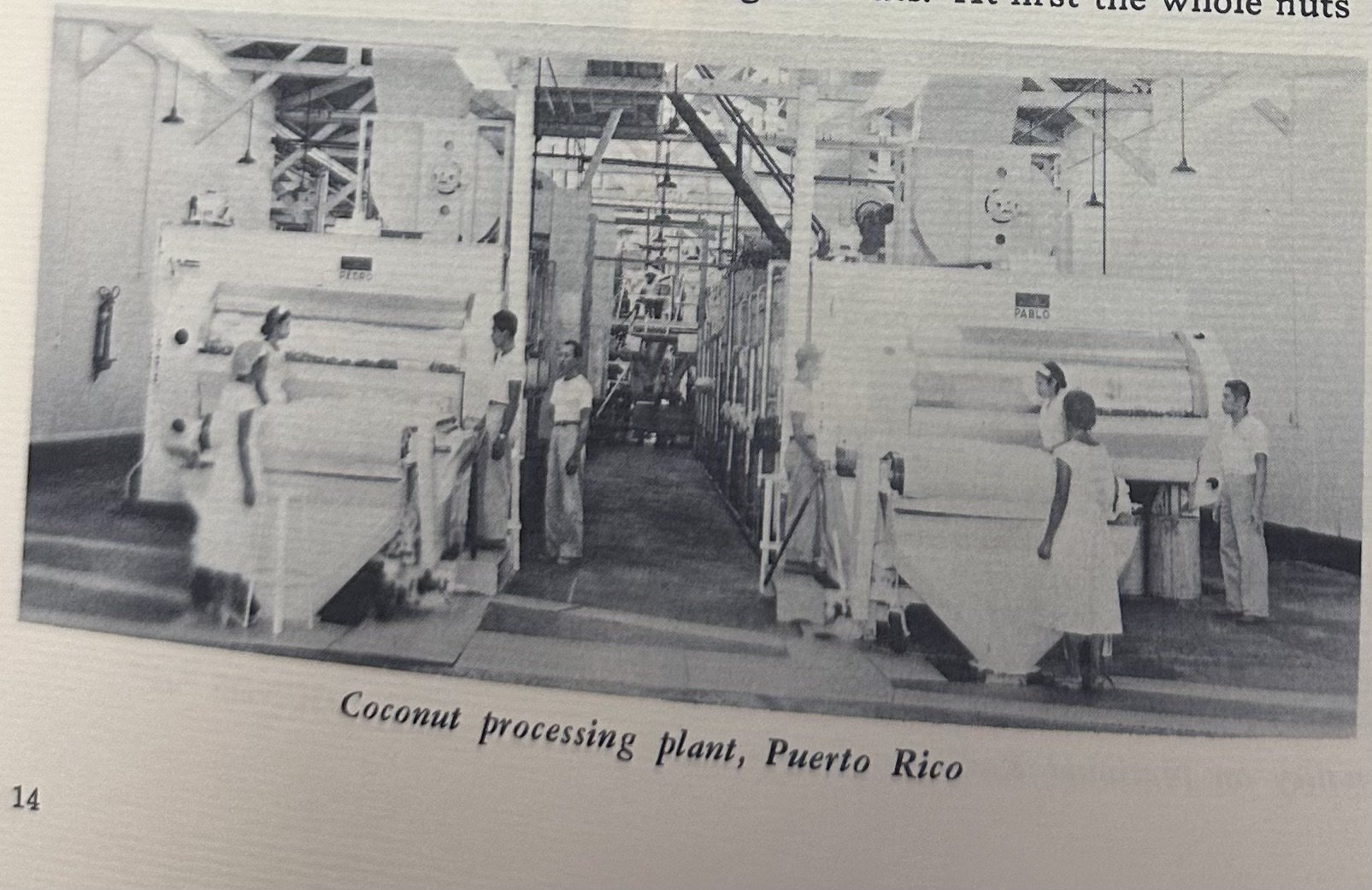

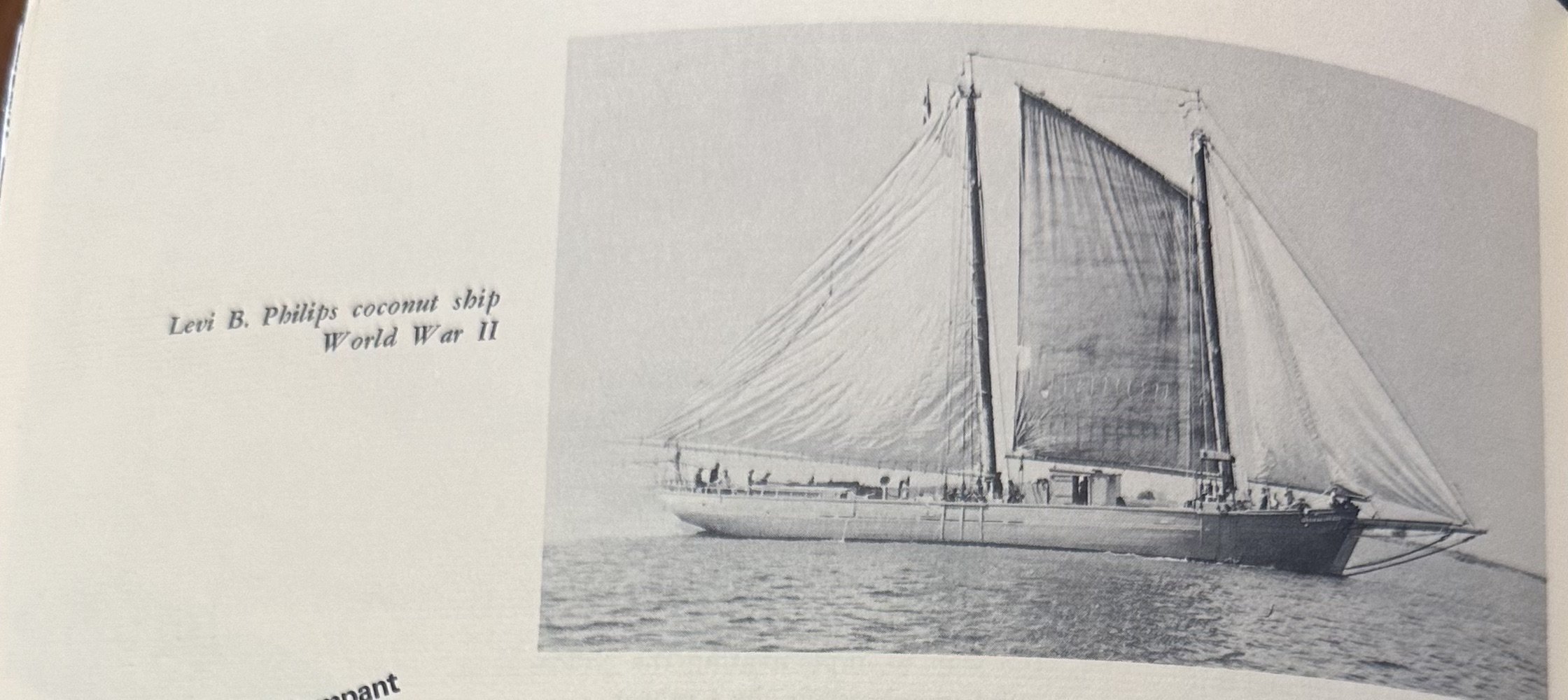

World War II presented a great challenge to the company. Early in 1942, Peter Paul lost its entire coconut supply when the Philippines were overrun by the Japanese. The company looked to the Caribbean for smaller coconuts found in that area. To bring the coconuts to the mainland the company bought a fleet of six or seven auxiliary schooners. The schooners were small, old and wooden, and soon became known as the “flea fleet.” The company thought that no German U-Boat would waste a torpedo on these ships, and none did. The schooners carried needed supplies to the islands and were occasionally able to report U-Boat sightings to Naval Authorities.

Because of the time and cost for the overland haul of Caribbean coconuts, a plant was also built and later replaced by one in Puerto Rico. When a fire destroyed this plant, it was quickly rebuilt and became a great asset to the company through the War years.

Sugar rationing and chocolate shortages severely limited production and made the job of maintaining high quality very difficult. The company looked for suggestions for substitute fillers.

Of the MOUNDS produced the armed forces received the largest amount, up to at least 80%. It was not those toffees that caramels, requiring little sugar and no milk or chocolate or coconut, became so important to Peter Paul. Charcoal gum was produced during the War and kept employment up during those years.

As soon as World War II ended, the management moved to secure the supply of coconut, to grow it in a later time, in their own hands. A plant was built in the Philippines, the world’s densest area for coconuts. The construction took only 46 days, and by early 1946 The Peter Paul Philippine Corporation was producing coconut. It was about this time that the plant turned to making caramels and other rich butter candies. This new market held the Puerto Rico plant so it was sold to another company which kept most of the coconut work force.

At this time, gum making was discontinued and candy bars became the only candy Peter Paul made.

Wartime controls were lifted and the demand for candy was great.

Source

Naugatuck Historical Society Newsletter

Volume 12, Issue 4

July–August 2007

Peter Paul, Inc., Part III

Changes from World War II to the Present

By Sandy Clark

(The 2007 May–June and July–August newsletters recorded the origin and growth of the company)

Once the wartime controls were lifted after World War II, the Naugatuck company went on three shifts because the demand for candy was so great. The added shifts were insufficient, and by 1948 a new plant was built in Dallas.

Adding to Peter Paul’s growth at this time was the Almond Joy. Earlier introduced, it had the same coconut center as the MOUNDS, but was topped with a whole chocolate. A machine was developed to place an almond on the center of the bar. It was an instant success, with a sales rank equal to MOUNDS.

Also in 1948, two of its founders died- Cal Kazanjian, who had been president since 1927 and Jacob Hagopian, treasurer of the company. George A. Shamlian, who had served as secretary and vice-president, was elected president. John Tatigian, the son of a respected candy maker from Bridgeport, was named vice-president. He had joined the company after college and quickly moved up the ranks to vice-president of manufacturing and in 1951 to the presidency.

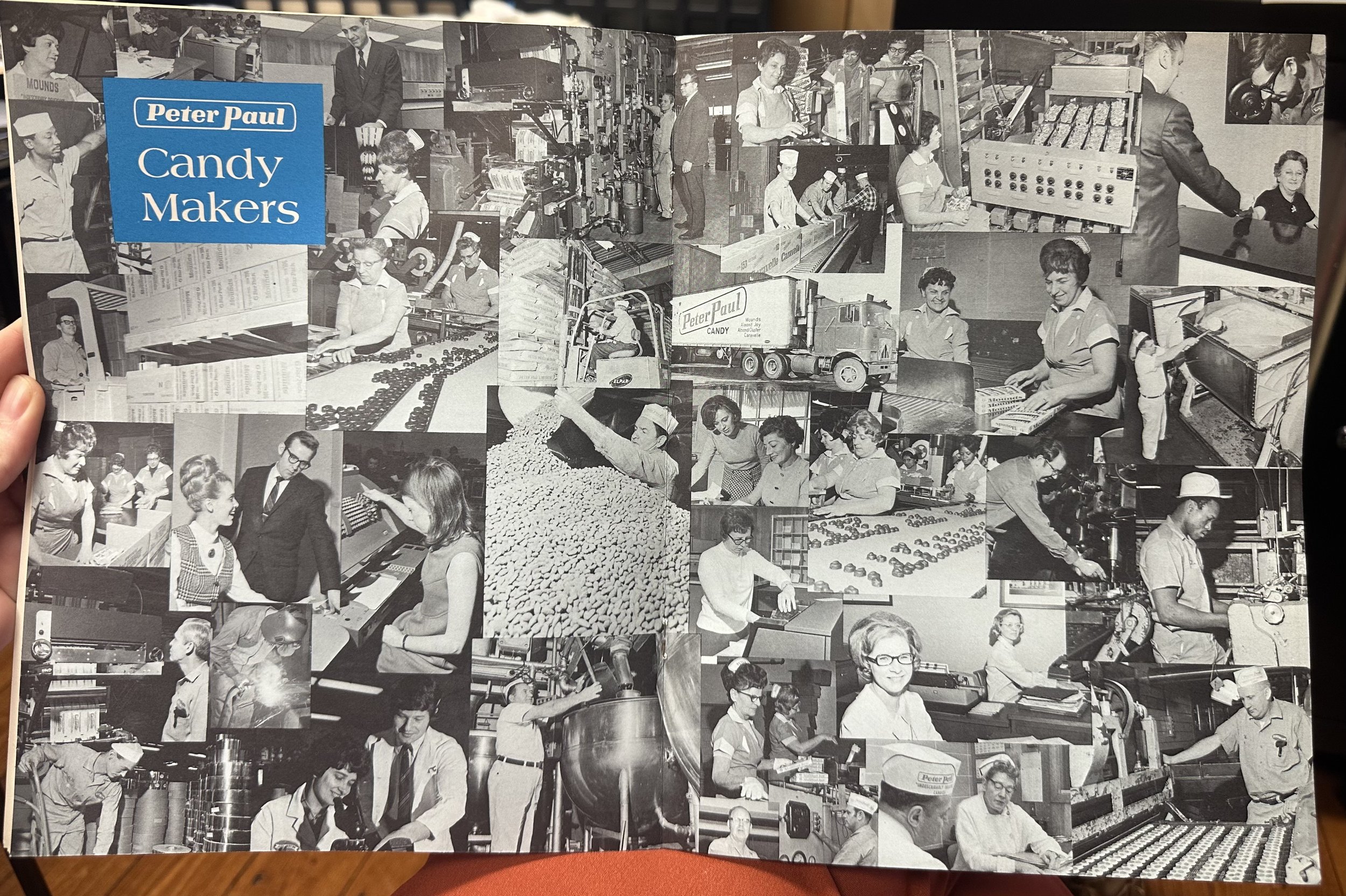

John Tatigian’s term as president was a period of consolidation, improving production efficiency and modernization. These moves reflected his father’s emphasis on quality of production and freshness of candy.

In the mid-fifties, Peter Paul led the industry in the use of network T.V. The Peter Paul pixies became national celebrities, and everyone learned to say “Indescribably Delicious.” T.V. commercials were a perfect medium for depicting the mouth-watering goodness of coconut and chocolate in full color.

To ensure the freshest candy possible for the Midwest section of the U.S., plants were built in Frankfort, Indiana (1958) and in Salinas, California (1965).

New bars were introduced during John Tatigian’s presidency. In 1959, the Almond Cluster, a combination of milk chocolate, malted milk crunch and chopped almonds, was marketed. A new success was born in 1965, “CARAVELLE,” a combination of soft caramel, crispy rice, brazil nuts and rich milk chocolate. An instant success, it was voted best new candy in 1967.

The year 1966 saw the retirement of John Tatigian and the acquisition of the Walter H. Johnson Candy Co., maker of the famous Power House bar. In January 1966, Peter Paul became its own supplier of chocolate when it purchased the Bachman Chocolate Manufacturing Co.

In 1972, Peter Paul acquired the York Peppermint Pattie, a unique candy with a special “grainier” coating center distinguishing it from other mint patties. In the same year, Peter Paul introduced PEANUT BUTTER with no jelly, a tasty candy with a soft peanut butter center laced with bits of rice and covered with milk chocolate.

Peter Paul became an international dimension in July 1968 by buying 51% of the C.J. Van Hooten & Zoon Co. in the Netherlands. This company had a worldwide reputation for cocoa and chocolate products. The purchase brought the famous Peter Paul brands to the European market.

In 1978 Peter Paul expanded its global dimension when it merged with England’s Cadbury Ltd. and became known as Peter Paul/Cadbury. This union remained in effect until Peter Paul was bought by Hershey Foods Corporation in 1988.

The words “made in Naugatuck” soon faded from the MOUNDS and Almond Joy labels, but they kept rolling off the Naugatuck assembly line. More new products were introduced: Almond Joy Pina Colada, in 2004, and Almond Joy White Chocolate, Key Lime and Milk Chocolate Passion Fruit in 2005.

By April 2007, Hershey announced the closing of its plants in Ontario, and Reading, PA. And the loss of 900 jobs in three other Pennsylvania plants. Naugatuck was not far behind. The plant will close by November, and the Peter Paul Co. will fade away into the annals of Naugatuck’s history.

During much of the history of the company, Peter Paul did insist on “quality and freshness in its candies.”

Source

Naugatuck Historical Society Newsletter

Volume 12, Issue 5

September - October 2007

Images of America - Naugatuck & Naugatuck Revisited Dana J. Blackwell and The Naugatuck Historical Society (November 1, 1996) Ron Gagliardi (August 25, 2004)

Naugatuck Stories and Legends I & II. William G. Leuchars (1969)(1977)

1969 Annual Report

1977 Annual Report

1977 Annual Report

1969 - 50 Years Edition

1969 - 50 Years Edition

1969 - 50 Years Edition

1969 - 50 Years Edition

1969 - 50 Years Edition

1969 - 50 Years Edition

Undated

Online Resource Library

Community Contribution

Now let’s move on to the main topic of this week’s episode, something that is also often a big part of the Christmas season – candy! As a child, (and let’s be honest, even to this day,) I am always very pleased to see some of my favorite candy bars in my stocking on Christmas morning. One of Naugatuck’s greatest contributions to the world almost exactly one hundred years ago, was a pair of candy bars that still remain best sellers as we approach 2021.

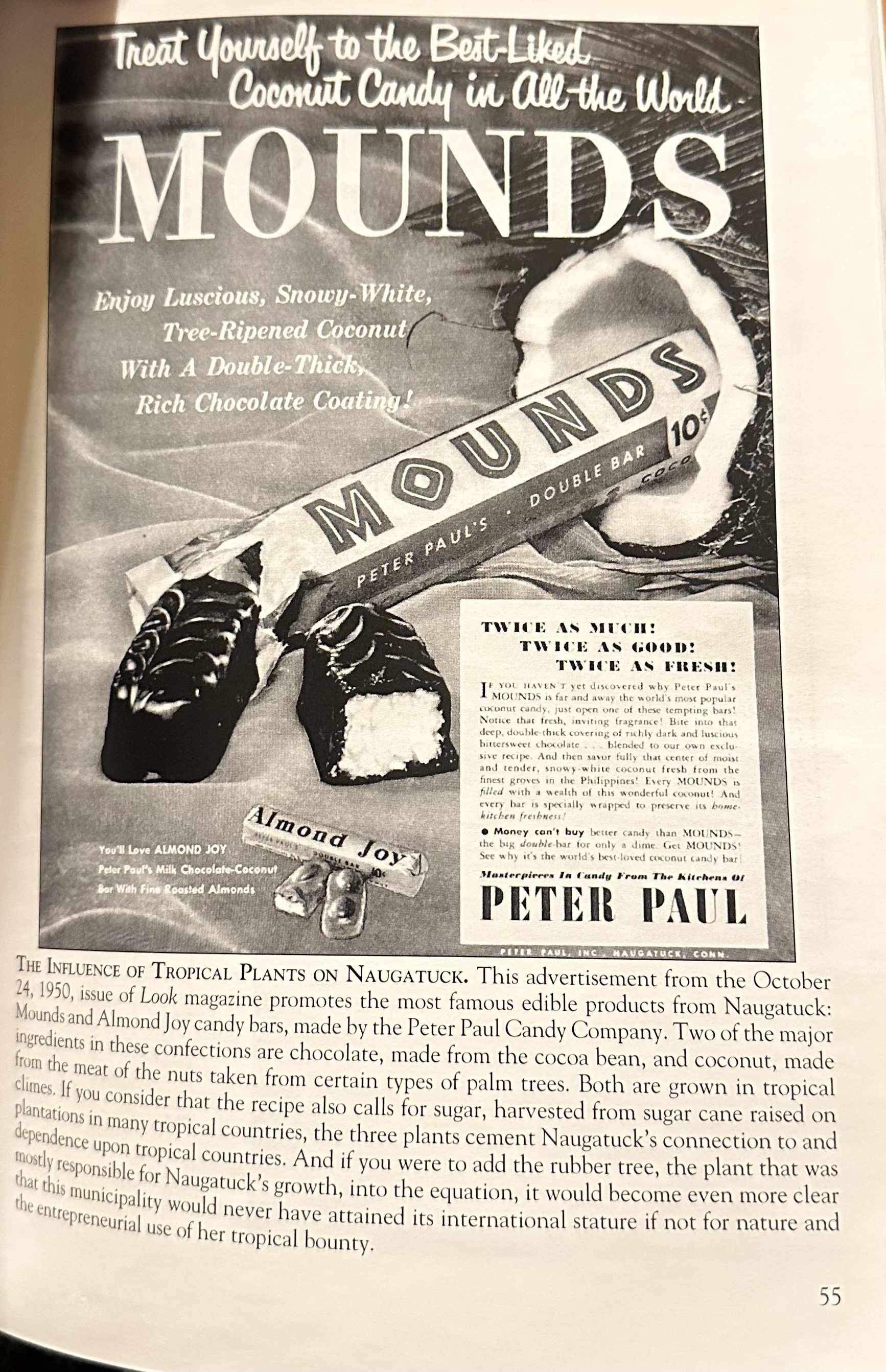

In 1921, the Peter Paul Candy Manufacturing Company introduced the Mounds candy bar, a dark chocolate-covered "mound" of coconut, and it was an instant success.

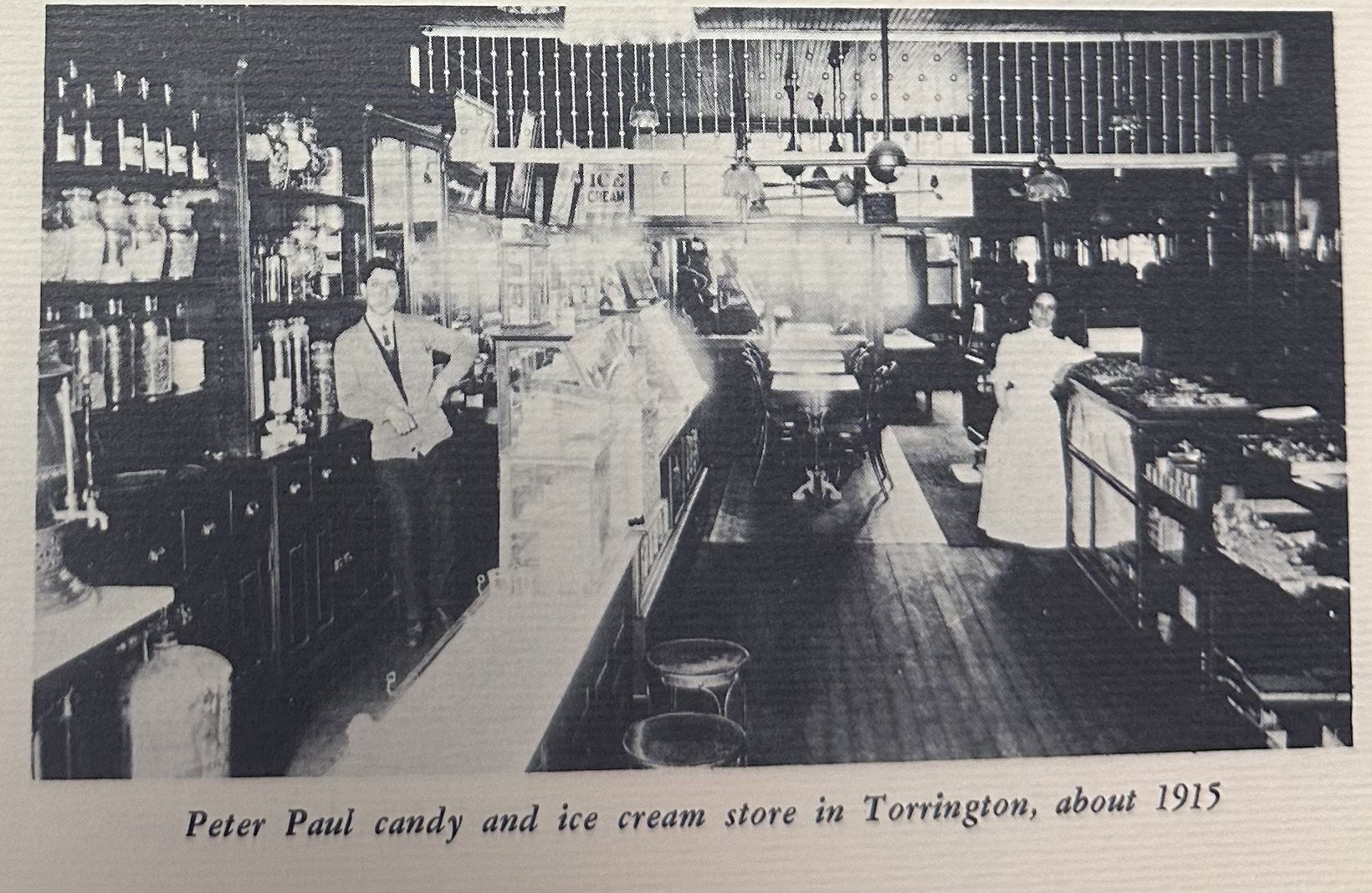

“The founder of the company was an Armenian immigrant by the name of Peter Halajian who landed in the United States in 1890. Thrift in time established him as proprietor of a small chain of candy stores in Naugatuck and Torrington, Connecticut, where he sold confectionery and ice cream of his own making. Because his customers found difficulty in pronouncing his Armenian name, he legally adopted the English equivalent, Peter Paul.”

After arriving in Naugatuck, Halajian began working at the U.S. Rubber Company, like so many immigrants before and after him. While working there, he dreamed of starting his own business, and made efforts in that direction by selling homemade sweets to folks waiting for the train at the Naugatuck Railroad Station. Soon he added fruits and other confections to his menu and with his daughters now helping, they expanded the business with door to door sales throughout the town.

On February 1st, 1895, Peter realized his dream of entrepreneurship and opened a small candy shop on Water Street in Naugatuck. The items on sale included peanut brittle, licorice, lemon drops, chocolates, and most famously, ice cream! Success led to a second store in Torrington and in 1912 a third store opened, also in Naugatuck. As sales increased, so did the frequency of customers having trouble pronouncing his Armenian surname, Halajian. This prompted him to legally change his last name to its English translation; Paul. It was not long before the name Peter Paul became synonymous with delicious candies.

Business continued to grow, and Peter started advertising, creating the clever slogans that his company would become known for. With the expansion came the need for more help, and soon Peter’s brother-in-law Calvin Kazanjian joined the firm.

In 1914, World War I plunged the globe into terrible conflict. One of the most welcome reminders of home for the doughboys in Europe was a chocolate bar. The U.S. Army provided the candy bars as a high-energy food that would be durable and remain edible in the dangerous environment of the front lines. After the war ended and the soldiers returned home, they brought their love of candy bars home as well.

It was Calvin who had the idea to capitalize on this new market opportunity by switching the business from one of retail, to a larger manufacturing concern that would offer candy as a wholesaler. The partners convinced four of their close friends and relatives to invest in the business. A close-knit group of fellow Armenian immigrants; George Shamlian (a former chemist with Naugatuck Chemical,) Jacob Hagopian, Harry Kazanjian and Jacob Chouljian provided the money required. They also brought in candy maker, Harry Tatigian.

In 1919 the Peter Paul Candy Manufacturing Company was born and moved their candy-making operations to New Haven. The new company began production in November of that year, making candies by hand in a 50 x 60 foot loft on Webster Street. Lacking a means to refrigerate their products, production took place during the coolness of night and the results shipped out immediately the next morning for maximum freshness. Initially, their confections were much like other candy makers' but they knew they had to innovate. The original “Konabar,” a chocolate covered coconut candy also containing fruit and nuts became an early success for the company.

Lisa Flaherty, great-granddaughter of Harry Tatigian wrote:

"Harry Tatigian was my great-grandfather by blood, but unfortunately died in the early 1920's. An interesting footnote is that my great-grandmother fell in love again, and married George Shamlian (who's mentioned above as one of the founding fathers of the company). George helped her raise the son she had had with Harry – my grandfather, John Tatigian. So it was George, who became "Dad" to my grandfather and, thus "Grandpa" to my Mom and Uncle. He was VP of the company until becoming its 3rd President. My grandfather John joined the company in 1931 and became the 4th President in 1951 when his father retired."

Clearly, the founders of Peter Paul were a tightknit group, and that family atmosphere remained a hallmark of the business throughout its history. Paul became the company’s first president; George Shamlian became vice president, and Kazanjian became secretary/treasurer. Kazanjian was also in charge of creating and managing a sales department of commissioned agents. Finding retailers willing to sell the products of the new company was priority number one. Cal’s cousin Artin Kazanjian and Jacob Chouljian were both hired as foremen of operations. Chouljian’s cousin Jacob Hagopian became assistant treasurer. Chouljian would later marry one of Cal Kazanjian’s sisters, further cementing the family aspect of the company.

Demand for their products kept rapidly increasing, and it was no longer possible to keep up using the hand-made manufacturing techniques of their small candy kitchen. Expansion was a necessity, but New Haven bankers were not willing to provide loans to a candy-making business, deeming it too risky.

"Assembling the new product was laborious. The candy had to be shaped, rolled, dipped by hand in chocolate, and then wrapped in foil." "Originally, Mounds was hand-dipped, and then hand-packaged in a foil wrapper. Then, when they got automated machines to shape and wrap it, it was wrapped in cellophane. Eventually, it was given the paper it's in now."

Convincing Peter Paul to build their candy factory in Naugatuck was the first major achievement of the newly created Naugatuck Chamber of Commerce, which had been established in the fall of 1921. In what is perhaps the most significant "first" for Naugatuck, Peter Paul began mass producing the Mounds bar at their newly built factory on New Haven Road.

The history behind the invention of Mounds varies based on the sources you read. In some stories, it was invented by Vincent Nitido, a candy maker from West Haven.

"Vincent Nitido Sr., as a brilliant mind in the industry of candy-making who created the famous Mounds bar 100 years ago. Nitido Sr., a West Haven resident at the time, introduced the dark chocolate and coconut-filled candy bar in 1920 as a single piece for 5 cents."

In that version, it was purchased by Peter Paul and manufacturing began in 1929. That date may be subject to interpretation, especially if the candy was already being manufactured by Peter Paul since 1921, perhaps by an earlier agreement.

In another version of its invention, according to Lisa Flaherty, great-granddaughter of Harry Tatigian, the original Peter Paul candy maker, George Shamlian is credited:

"Mounds was introduced in 1920. George Shamlian researched and developed the Mounds' formula. Mounds was created to replace their already-existing Coconut Cream Bar. The coconut cream bar, peanut brittle, lolly pops, among others were the first Peter Paul candies."

Still another version seems to agree with Flaherty's.

"It was Shamlian, a chemist, who came up with the recipe in 1920 for what was to be known as the Mounds Bar - a dark chocolate bar with a creamy coconut filling named after the way it looked."

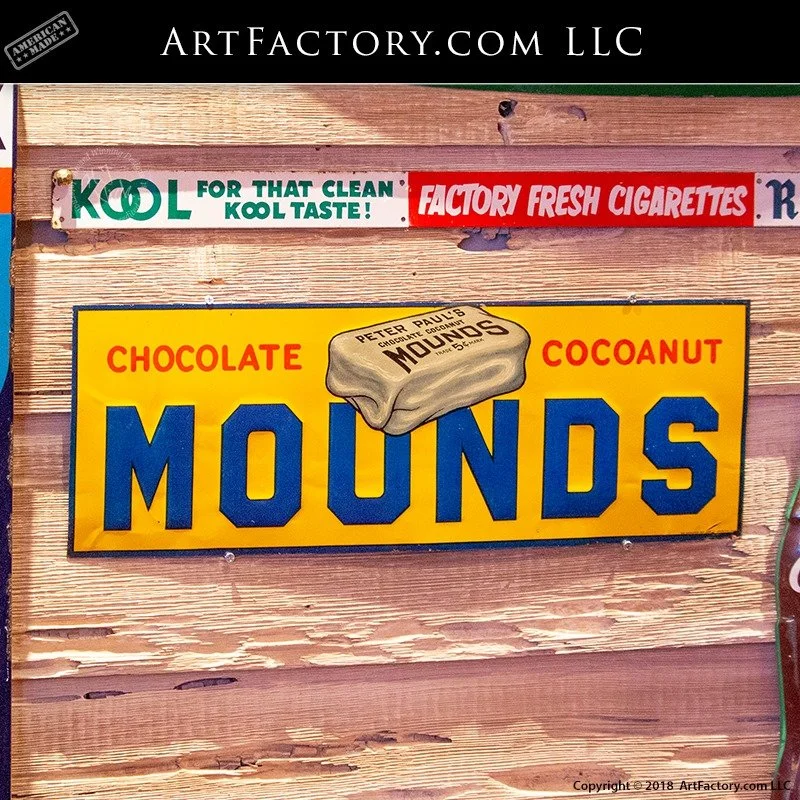

No doubt there is a combination of both origins that most likely accounts for the Mounds bar becoming an iconic Naugatuck product. In the photos many vintage packages and wrappers can be seen, some featuring the name of our town.

In 1934, Peter Paul expanded yet again, with a $60,000 addition to the plant. Even more money was invested in new machinery to meet demand, but current earnings covered the costs, and the company incurred no debt. In yet another interesting "first," that same year, Peter Paul introduced the first candy bar named by the students of a high school. The Dreams candy bar, got its name from students participating in a contest at Naugatuck High School. It featured chopped almonds and coconut covered by dark chocolate. It was the forerunner of the Almond Joy bar, and for a number of years, it was a national best-seller!

Another amazing story of the company, may not be an actual "first," but it was so sensational that it made national headlines. In February 1935, Peter Paul increased wages paid to their employees by as much as 20%, and the company's stock split two for one. The story spread around the country, carried by the Associated Press. Bucking the national trend, Peter Paul's stockholders received continuous quarterly dividends throughout the Depression.

In 1939, another World War ravaged the globe and Peter Paul became a major supplier to the U.S. Military. So much so that folks at home had to go without. The government was purchasing 80% of their production by 1944, up to 5 million candy bars per month, to include in soldier's rations. Folks at home willingly sacrificed their love of the delicious chocolates so that the boys on the front lines could have a little reminder of home.

"It was stated by the company that practically all Peter Paul production is now going to the armed forces of the nation, as has been the situation since the outbreak of the war. These delicious products are made available to the U.S. fighting men at home and overseas, with very little left over for civilian consumption. Peter Paul officials however feel sure that the American public would want the situation that way and are willing to wait, until the victory over Japan is won and the normal supply of these world popular confections are again available everywhere for everyone."

Still another "first," or "firsts" perhaps, involves the "Flea Fleet" of World War II. Not only was Peter Paul the first candy company to create its own "navy," but they also served as spies for the U.S. Military!

At this point in their history, Peter Paul had become the world’s largest consumer of coconuts, and they needed the vital raw material or the entire company would cease to exist. When its main supply from the Philippines was cut off by Japanese military actions, Peter Paul cobbled together a fleet of small ships and sent them to islands in the Caribbean to buy coconuts. The “Flea Fleet” was too small to be noticed by the Germans and Japanese, but the reverse was certainly not the case. The stealthy crews were able to slip undetected through enemy waters gathering valuable intelligence about Nazi ships.

Still more shocking, Mounds was the first candy bar to be involved in an international incident involving the Nazis. On July 20, 1945, the following headline shocked the readers of the Naugatuck Daily News;

"German General Is Found To Be In Possession Of Peter Paul's Mounds"

In the photos, you can see the headline, at the very top of the paper.

Apparently a press photograph was taken of an American officer checking the German prisoner's baggage when the box of Mounds was discovered. It was surmised that the German had stolen the Mounds bars from an American PX on the European battle front.

In 1948, another "first!" The Almond Joy bar hit store shelves, as the next evolution of the discontinued Dreams bar. It was essentially a Mounds bar covered in milk chocolate instead of dark chocolate, and also featuring a single, whole double-toasted almond on top. Packaged in blue to differentiate it from the Mounds bar, it became an immediate iconic success, and remains so to this day, being almost as world-famous as its older brother. The number 1 and 2 best selling candy bars are often Mounds, followed by Almond Joy.

The 1950s also saw another iconic first from the company. Peter Paul was the forerunner in the use of television advertising, with the Peter Paul Pixies singing that Mounds and Almond Joys were “Indescribably Delicious.” The slogan was the result of a 1955 contest won by Leon Weiss of Gary, Indiana, who received a prize of $10. Using that now familiar jingle, Peter Paul went on to become the first candy manufacturer to use full-color TV commercials.

Here's a couple of vintage ads seen on TV...

1957 Mounds commercial:

In the 1970s, some times you felt like a nut!

The factory is long gone now, and Mounds and Almond Joy are currently owned and manufactured by candy giant, Hershey's. In 2007, Hershey’s shut down the Peter Paul Manufacturing plant in Naugatuck, which had been continuously producing Mounds for 85 years. Although they are no longer made in Naugy, and our town will not appear on their wrappers, over 100 years of amazing history will forever link Connecticut and our hometown of Naugatuck to the most famous candy bars in the world. Let's hope you get a Mounds bar or an Almond Joy in your Christmas stocking this year!

Excerpt from Naugatuck Daily News – Saturday, August 31, 1946

World War II - History EditionPeter Paul Put Sweets In Famed “K”, “C”, Rations

The outbreak of World War II found Peter Paul faced with the tremendous task of overcoming critical coconut supply problems. Before the war, all its coconut was obtained from the Philippine Islands; hence, when the Japanese overran the Islands, the company’s source of coconut was cut off.

Faced with the possibility of the discontinuance of their nationally known Peter Paul Mounds, a substitute candy bar, the management sought ways and means to restore its coconut supply by making a survey of the Caribbean area. These accounts were available in limited supply. It was not long before coconut processing plants were located at Tampa, Florida, and Arecibo, Puerto Rico; for the Caribbean area and west Central America.

However, acute shipping conditions and the submarine menace presented new difficulties in transporting coconut to the mainland. This problem was solved by the purchase and lease of a fleet of small 35 to 600 ton auxiliary schooners to supplement submarines considered too small to sink. These ships rendered valuable service in reporting to our Navy when enemy submarines were sighted. On return trips, by arrangement with government agencies, badly needed supplies were transported to Cuba, Puerto Rico, Honduras and other Central American countries.

Shells in War

Within a short time, Peter Paul was making a major contribution to the war effort, with coconut shells being furnished to chemical companies for the manufacture of activated carbon for gas masks and processes connected with the manufacture of high explosives. While its machine shops manufactured airplane parts.

Although the average person would not formally associate candy with aircraft, tanks and ammunition as a material of war, the Quartermaster Corps recognized early in the early stages of the war, the importance of candy as a quick source of energy and unusual aid in relieving fatigue and maintaining morale. At the PX’s, candy was one of the four top items in troop diet demand and second on the list of morale items handled by El Depot exchanges. Also, included in emergency rations issued by the Army and Navy continued candy and included Peter Paul’s Chocolettes in the now famous “C” and “K” combat rations. Approximately 5,000,000 bars of Chocolettes were packed monthly in these units.

Excerpt from Naugatuck Daily News – Monday, September 15, 1947

Industrial Exhibit Supplement

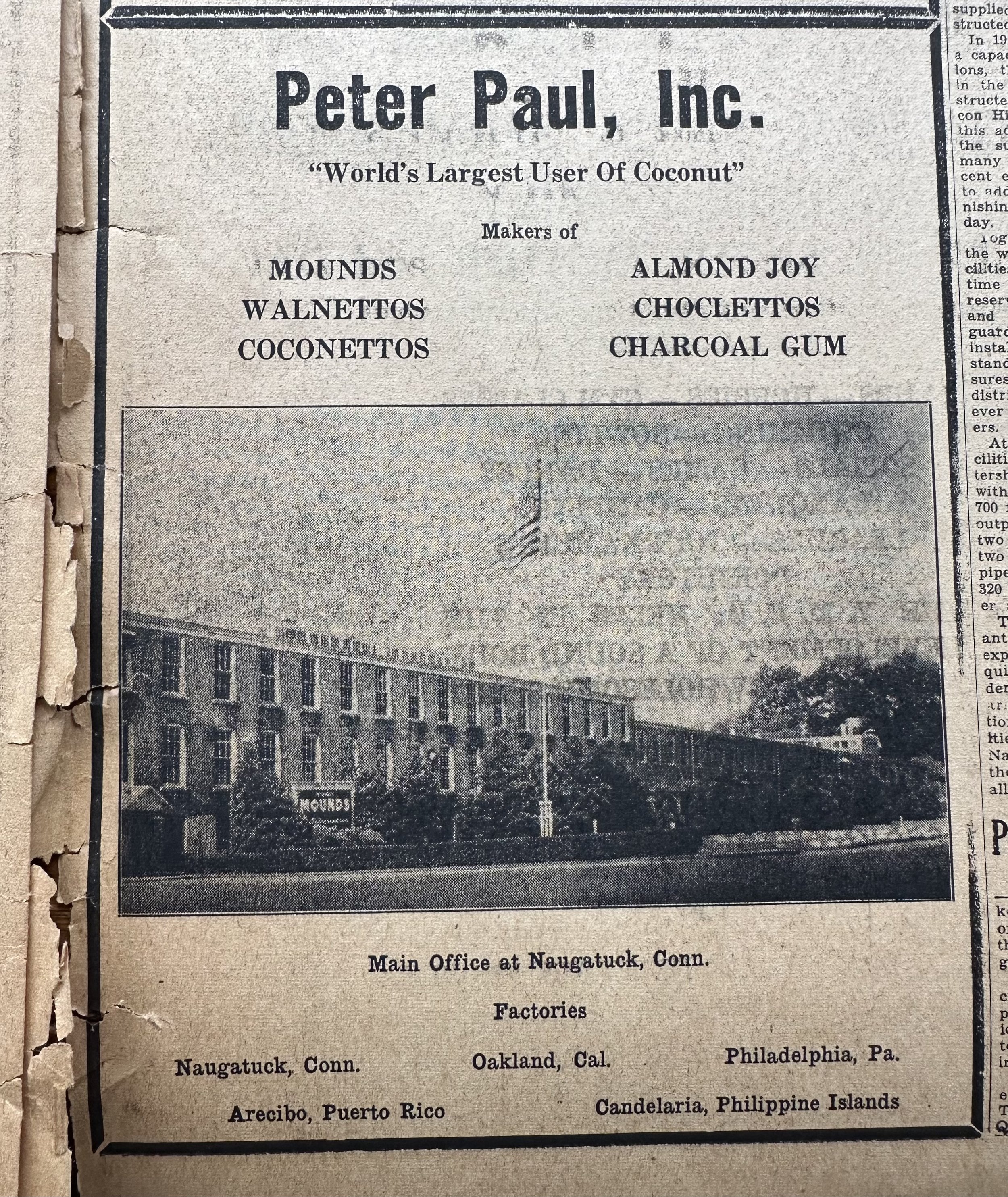

Flourishing Peter Paul, Inc. Started Candy Plant On Modest Scale In 1919

Naugatuck Banker Supplied Capital That Moved Firm Here from New Haven

Peter Paul Inc., of Naugatuck, Conn., is one of the country’s leading and fastest-growing producers of candy. With factories now in Naugatuck, Puerto Rico, Philadelphia, and Oakland, Calif., and a new factory soon to be started in Arecibo, Puerto Rico, Peter Paul is a symbol of economic and marketing ability fast reaching nearly war-time peaks. It comes through an organization whose single objective is to turn out the maximum amount of sweet, fine economy candies in the shortest possible time consistent with the company’s exacting manufacture of the world’s best.

The company was organized in 1919, when Peter Halajian (Paul) with five other associates, Calvin K. Kazanjian, George Shamlian, Jacob Chouljian, Henry Chouljian, and Jacob Hagopian, opened a small candy shop in New Haven. The increasing demand for their product made it necessary that they seek larger quarters, and through the financial aid of a group of Naugatuck bankers who were impressed by the men and their product, funds became available. Peter Paul moved to Naugatuck and began business in Naugatuck in 1922.

From 1924 to 1930 when the depression hit the country, the little candy company specializing in chocolate was acquiring a sound subsidiary. Peter Paul, Inc., progressed. Then came the depression and it closed. Candy manufacturers all over the country suffered. But where many went out of business, Peter Paul, Inc., in 1931, made a careful study of the candy business and sought to revise selling policies. One major step was to do away with outmoded, slow, unattractive wrappers and enclose tempting candy bars in cellophane for all to see. With chocolate and prime candy materials also having declined, greatly the savings in profit margin and increased demand made the management conceal the idea of passing on these savings in material cost to the consumer. Two small “MOUNDS” instead of one were packed together in a single wrapper and carried the same five cent price tag. Candy eaters throughout the country gave instant recognition to the full value offered them and in 1932, the worst year of the depression, Peter Paul’s sales mounted to record heights.

World War Problems

Before the war, most of the coconut came from the Philippines and that country, which faces both the Pacific Coast and the Atlantic Seaboard. The fall of the Philippines to the Japanese necessitated the company to seek a new source for its coconut supply. Knowing that coconuts were available in the Caribbean area, the company established connections in several Caribbean and Central American countries and continued to secure products from them. A complete factory in Arecibo, Puerto Rico.

After war shipping difficulties and restrictions ceased, the demand for candies zoomed and workers became hard to get. Peter Paul moved into the Philippines again, this time because of the value of coconuts. Because of the shortage of shipping and the long wait for the desiccated product, the company was the first to open a desiccating factory on site. The MOUNDS bar, product of a post-war industry, had become a war industry.

After the Japanese moved in on the Philippines, Peter Paul products were vitally important to the Services. Peter Paul, under a priority of the War Production Board, was permitted the purchase of sugar, chocolate, and coconut, for the manufacture of a candy bar which became a favorite of men and women in the Services. A great deal of the wartime output went into Army and Navy rations.

Peter Paul is looked upon in the Philippines not only by coconut men as the company that economizes time and labor, but by the native population as the company that is safeguarding the welfare of its employees. This is shown by the operation of the Puerto Rico coconut desiccating factory to a candy manufacturer rather than a coconut processor. For years, thousands of Puerto Rican workers who had worked so faithfully and hard were critical in the production of Peter Paul. At present, the production of the Caribbean factory includes:

COCOONETTES, delicious coconut candies, are being processed there.

The entrance of Peter Paul into the Puerto Rican industry has had a major effect in raising coconut prices, solid sales to the American worker, and those in the community whose lives have increased their standard of living immeasurably over pre-war days.

The Peter Paul factory in the Philippine Islands is an enlargement of the Puerto Rican operations. The development of this operation is another great expansion—an example of great enterprise.

With the development of postwar wider dissemination of products, Peter Paul’s experiment with desiccated coconut arriving at its factories from the Philippines and other locations such as the Caribbean has been greatly enlarged and sales increased, thus giving employment to hundreds of additional workers at wages higher than the confectionery industry.

As the demand for Peter Paul products increases every effort is made to improve flavor and merchandising and to offer retail dealers a wide variety of attractive merchandise. This is reflected in the company’s efforts to furnish a wide line of outlets for wholesalers and jobbers, who, in turn, service the retail candy stores.

For the purpose of giving every retail shop a chance to sell Peter Paul products, a great new Southwestern Statement is being distributed by representatives in Dallas, Texas. This agency is expected to cover the entire Southwest and distribute products to all points in that area.

Among original founders of the company still taking an active interest in its progress is Calvin Kazanjian, vice-president of the company, who maintains continuing interest in the business. Mr. Kazanjian is regarded as the company’s chief economist and has been both scholarly and remarkable in his accomplishments in his field. He is one of the few men who operates on the principle of the value of economics as both well-regarded in the plant, in the organization, and in the goodwill of employees, jobbers and consumers.

Products manufactured by Peter Paul include Mounds, Almond Joy, Charcoal Gum, Walnuttoes, Chocolettos and Coconettos.

Naugatuck Daily News – Monday, September 15, 1947

Naugatuck Daily News – Monday, September 15, 1947